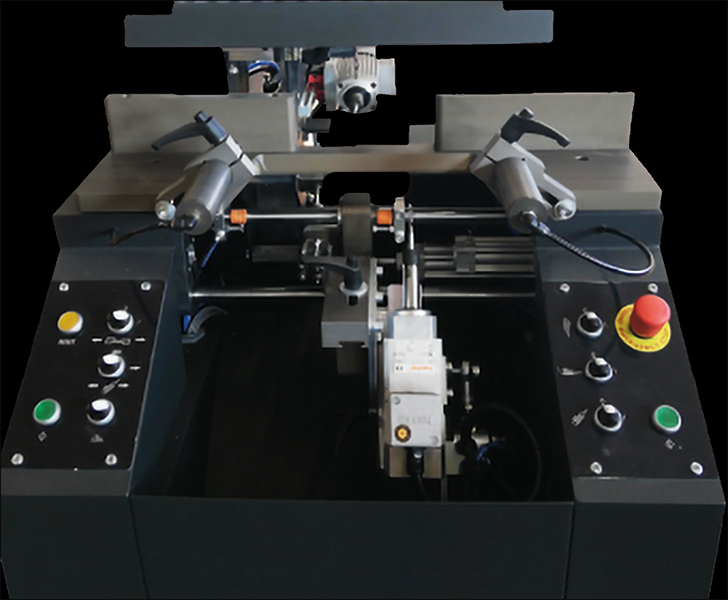

Controls and safety

An ergonomic control panel allows complete control of the machine by means of selector switches and dead man's buttons; the two-hand control button guarantees the safety of the operator and prevents accidental movements. The control panel also features an emergency button that allows the machine to be stopped immediately in the event of an abnormal situation, offering full protection to the operator.

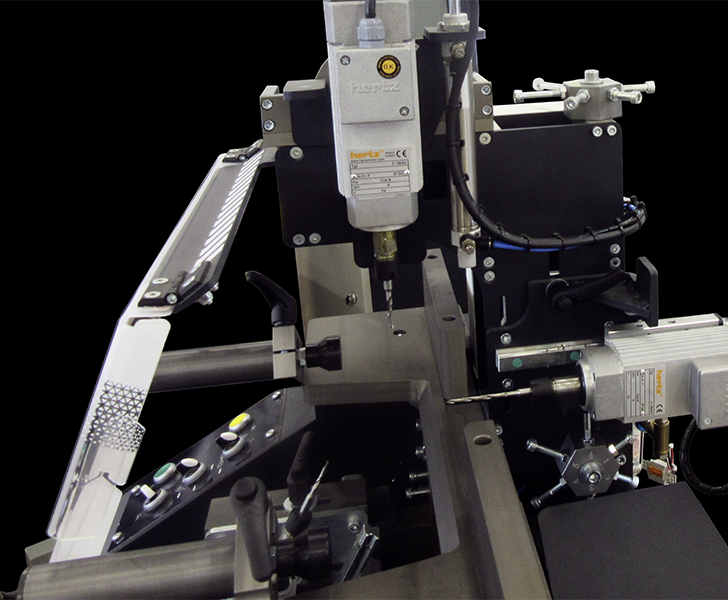

Milling units

The milling unit is driven by a high frequency electrospindle. The stops for head positioning run on recirculating ball bushings and are controlled manually. Pneumatic feed of the units is on recirculating ball slideways.

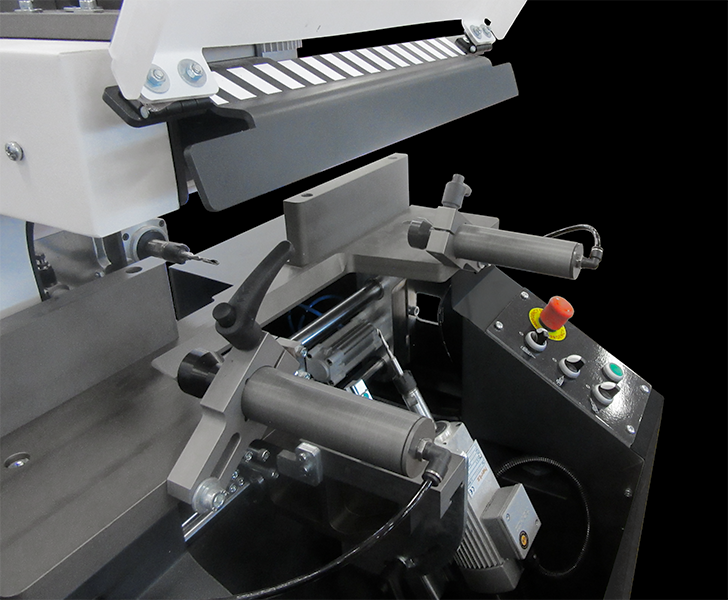

Work table

The table is equipped with an automatic bi-directional translation system that allows the creation of condensate drainage slots. The amplitude of the lateral movement can be adjusted manually by appropriately positioning the end stops.

Vices

Vice adjustment is manual in order to ensure correct clamping of the profile. The long stroke of the vices minimizes adjustments for the various types of profiles.

Adjustments

On each machining unit there are two revolver stops with 6 adjustable positions that memorise the working depths and positioning with respect to the workpiece. The vertical and the inclined milling units can be tilted to allow machining on non-orthogonal surfaces. The tilting adjustment is manual and covers an arc that allows machining of all types of profiles.

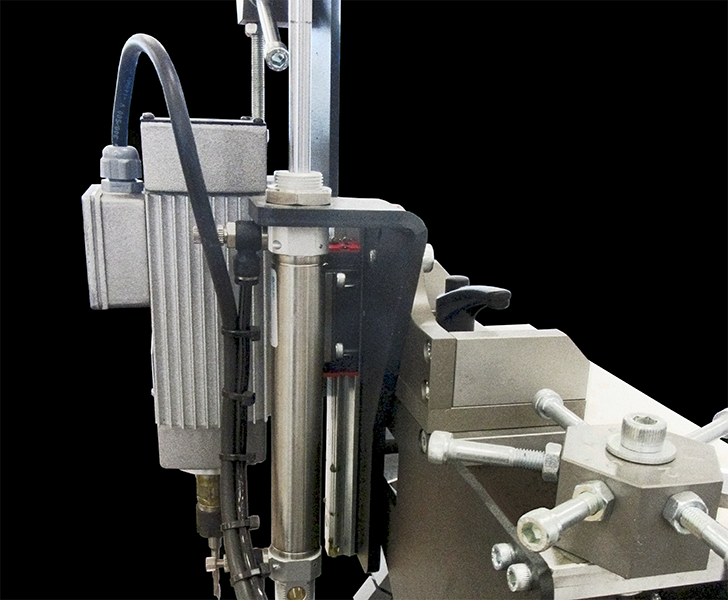

Economy of operation

The feed of the three high-frequency electrospindles on guideways and recirculating ball shoes is driven by a pneumatic cylinder. This solution ensures smooth automatic movement, guaranteeing high precision, minimal maintenance and low energy consumption.